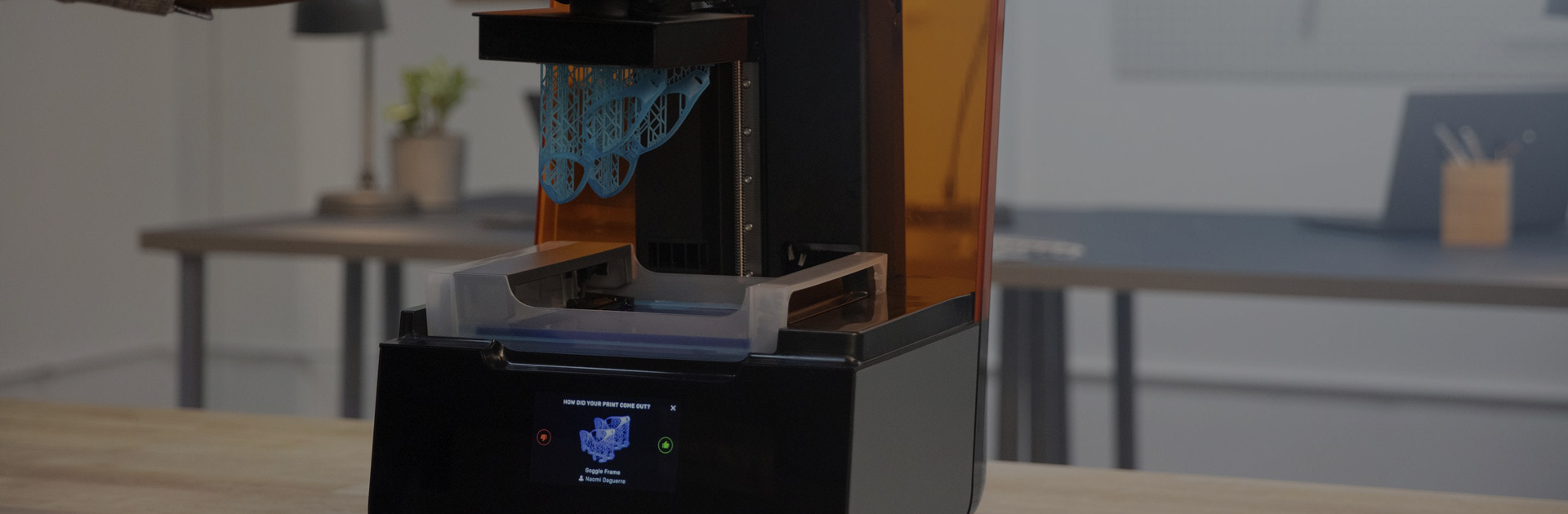

Today, with the rapid development of science and technology, I believe you are no stranger to 3D printing. Today, 3D printing technology has been applied to many industries in succession without the concept of gorgeous and abstract. In this new industry with great potential, GSE modular nitrogen generator has helped the 3D printing industry.

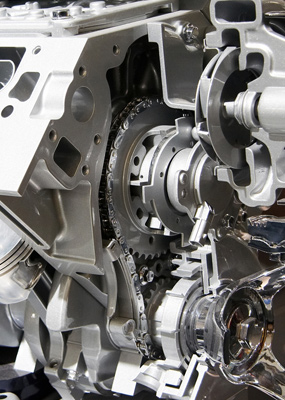

As a cutting-edge and potential technology in the whole 3D printing system, 3D printing technology for metal and nylon parts is an important development direction of advanced manufacturing technology. Metal 3D printing has a wide range of applications, such as biomedicine, teeth, artificial bones, aerospace, automobile manufacturing, industrial molds, etc.

Metal and nylon 3D printing equipment usually has a sealed reaction chamber, which can not only prevent the leakage of some toxic and harmful by-products, but also eliminate the impact of oxygen on materials. Therefore, the sealed reaction chamber needs to be filled with inert gas to prevent metal powder and nylon powder from being oxidized in the high temperature of laser irradiation and reduce the strength and ductility of printed objects.

As an economical and easily available gas with stable chemical properties, nitrogen is the gas solution for metal and nylon 3D printing equipment.

|

Popular products in the industry Model:NPM08 Nitrogen flow:11~40m³/h (180~666L/min) Nitrogen purity:99%~99.999% Nitrogen pressure:0.6MPa Equipment size:1100×470×1690mm(L×W×H) |