Application of nitrogen in laser cutting

Laser cutting uses nitrogen to solve many processing problems in actual production, and expands the processing range to the fields where oxygen cutting is difficult to process, such as aluminum and brass. The following describes its applications in various materials and fields.

1. carbon steel

Carbon steel is cut with oxygen. The surface temperature is very high due to carbon assisted melting and oxygen combustion. When cutting holes with sharp corners and diameters smaller than the material thickness, too much heat is concentrated in the narrow area, so that the cutting quality cannot be guaranteed. Nitrogen does not assist in combustion and has a cooling effect, which is suitable for solving such processing problems and can improve product quality.

2. stainless steel

In consideration of cost, the oxidation of cutting edge does not affect the use of stainless steel parts. Oxygen cutting is used. However, the content of alloy elements such as Ni in stainless steel is large, the viscosity of melt is large, and the fluidity is poor. The low air pressure during oxygen cutting is easy to lead to quality defects such as slag sticking. When welding stainless steel, the oxidation layer seriously affects the welding quality, especially argon arc welding. Nitrogen cutting provides high-quality non oxidation section, which meets the high requirements of stainless steel welding for cutting section.

3. aluminum and brass

Aluminum and brass have high reflectivity and low absorptivity to laser, which requires high power to melt materials. In addition, it shall be equipped with a reflection and absorption device so that the uneven linear wave will not be reflected back to the lens to protect the safety of the laser. Nitrogen cutting is required.

The melting point of aluminum is low. Oxygen can be used to cut aluminum with thickness less than 3mm, but the quality is very poor, and the section has hard burrs. The nitrogen cutting section is smooth, and the effect of no burr can be obtained if the thickness is less than 4mm. Due to the high viscosity and thermal conductivity of aluminum, the melt may have cooled before blowing away, so burrs are easy to appear. Reduce the surface roughness value by adjusting the focus, increasing the air pressure and reducing the speed, so as to ensure that the burr can be easily removed.

4. etching

Etching is a kind of special cutting, and the energy is only 5% of the basic power. It only acts on the surface of the material and is mainly used for etching marks. The oxygen etching temperature is high, and sometimes there is welding slag on the surface. Concentrated etching can also damage the surface of parts due to heat concentration. Nitrogen etching is bright and does not damage the surface. It can be used to etch instructions with high requirements.

Oxygen cutting has large thickness and low cost. It is mainly used in carbon steel. The cooling and protection of nitrogen improves the cutting quality, and has achieved good results in cutting stainless steel, aluminum and brass, and solved many processing problems.

In addition, it can be used to process wood, plexiglass and other special materials without auxiliary combustion, which has a broad application prospect.

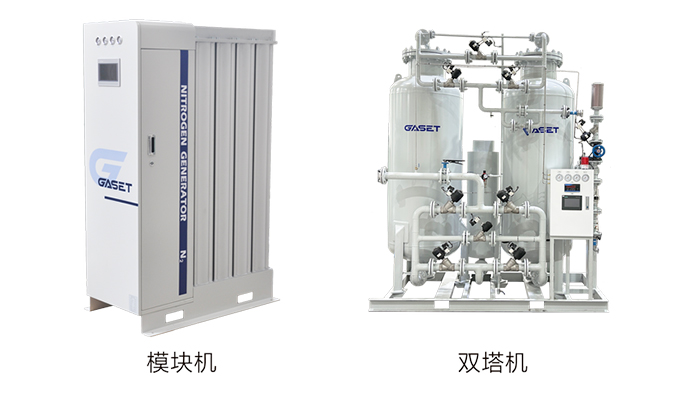

GSE Tech(Suzhou)Co.,Ltd.

MB:+86 512 65111668

E-mail:ziyi.ying@gsetech.cn

Add:Building13-1,No.58,Sunshine Avenue,Changshu City,Jiangsu Province