Key technical equipment in the 3D printing industry

Release time:2019-09-22 Number of views:1013

With the widespread application of 3D printing technology in aerospace, medical dentistry, automotive manufacturing and other fields, a modular and efficient nitrogen production equipment is quietly becoming an important driving force for the high-quality development of the industry.

In the rapidly developing field of 3D printing today, the oxidation protection of metal powder during laser melting directly affects product quality and performance.

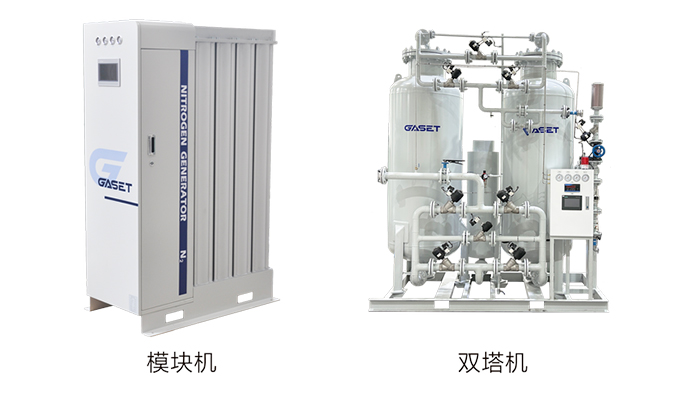

Traditional nitrogen supply methods such as steel cylinders and canned liquid nitrogen are gradually being replaced by a more efficient and economical technology - modular nitrogen generators, which use pressure swing adsorption (PSA) technology to directly separate nitrogen of the required purity from the air, providing an unprecedented gas solution for 3D printing.

Inert gas protection requirements for 3D printing

In metal 3D printing processes such as selective laser melting (SLM), metal powders are prone to oxidation at high temperatures, leading to defects or even failure of the finished product.

The high-purity inert gas environment surrounding the metal powder bed of the 3D printer is key to ensuring printing quality, as it can effectively prevent metal oxidation during laser melting.

Nitrogen, as an ideal protective gas, plays multiple roles in the 3D printing process: preventing oxidation of printing materials at high temperatures, cooling the print head to reduce heat accumulation, improving printing accuracy, and ultimately enhancing product quality.

For different printing materials, the required inert gases also vary - argon is used for steel and titanium, while nitrogen is suitable for printing aluminum.

Technical principle of modular nitrogen generator

The modular nitrogen generator adopts pressure swing adsorption (PSA) technology to directly separate nitrogen from the air. 78% of the air is nitrogen, which means the nitrogen generator will never stop producing nitrogen according to demand. This technology utilizes carbon molecular sieves (CMS) as adsorbents to separate air and produce high-purity nitrogen gas at room temperature, with a stable purity of up to 99.999%.

Modular design allows users to flexibly expand their nitrogen production capacity according to actual needs, simply adding CMS modules to increase gas production. This feature is particularly suitable for 3D printing enterprises with continuously expanding production scales.

Advantages of modular nitrogen generator

Compared with traditional gas supply methods, modular nitrogen generators have shown significant advantages in the field of 3D printing. It can generate nitrogen in real time, avoiding nitrogen storage and transportation, greatly improving production efficiency. In terms of cost, the modular nitrogen generator has both low purchase and operating costs. Compared with traditional nitrogen supply methods, it can significantly reduce the procurement and transportation costs of nitrogen. High quality components ensure uninterrupted supply of nitrogen 24/7, meeting the needs of continuous operation in industrial production. The modular nitrogen generator has a compact structure, making it easy to connect to existing compressed air systems and plug and play, greatly improving the usability of the equipment.

Market prospects and development trends

According to market research reports, the 3D printing gas market is maintaining stable growth, with nitrogen being an important component.

Modularization, intelligence, and energy efficiency have become the main directions for the development of nitrogen generator technology. The latest generation of nitrogen generators is equipped with features such as purity monitoring, optional fail safe shutdown, and environmental protection mode, maximizing energy efficiency and reducing operating costs. With the penetration of 3D printing technology into more industries, the demand for efficient and economical gas solutions will continue to grow, and modular nitrogen generators are expected to become the standard configuration for more 3D printing enterprises.

In the rapidly developing field of 3D printing today, the oxidation protection of metal powder during laser melting directly affects product quality and performance.

Traditional nitrogen supply methods such as steel cylinders and canned liquid nitrogen are gradually being replaced by a more efficient and economical technology - modular nitrogen generators, which use pressure swing adsorption (PSA) technology to directly separate nitrogen of the required purity from the air, providing an unprecedented gas solution for 3D printing.

Inert gas protection requirements for 3D printing

In metal 3D printing processes such as selective laser melting (SLM), metal powders are prone to oxidation at high temperatures, leading to defects or even failure of the finished product.

The high-purity inert gas environment surrounding the metal powder bed of the 3D printer is key to ensuring printing quality, as it can effectively prevent metal oxidation during laser melting.

Nitrogen, as an ideal protective gas, plays multiple roles in the 3D printing process: preventing oxidation of printing materials at high temperatures, cooling the print head to reduce heat accumulation, improving printing accuracy, and ultimately enhancing product quality.

For different printing materials, the required inert gases also vary - argon is used for steel and titanium, while nitrogen is suitable for printing aluminum.

Technical principle of modular nitrogen generator

The modular nitrogen generator adopts pressure swing adsorption (PSA) technology to directly separate nitrogen from the air. 78% of the air is nitrogen, which means the nitrogen generator will never stop producing nitrogen according to demand. This technology utilizes carbon molecular sieves (CMS) as adsorbents to separate air and produce high-purity nitrogen gas at room temperature, with a stable purity of up to 99.999%.

Modular design allows users to flexibly expand their nitrogen production capacity according to actual needs, simply adding CMS modules to increase gas production. This feature is particularly suitable for 3D printing enterprises with continuously expanding production scales.

Advantages of modular nitrogen generator

Compared with traditional gas supply methods, modular nitrogen generators have shown significant advantages in the field of 3D printing. It can generate nitrogen in real time, avoiding nitrogen storage and transportation, greatly improving production efficiency. In terms of cost, the modular nitrogen generator has both low purchase and operating costs. Compared with traditional nitrogen supply methods, it can significantly reduce the procurement and transportation costs of nitrogen. High quality components ensure uninterrupted supply of nitrogen 24/7, meeting the needs of continuous operation in industrial production. The modular nitrogen generator has a compact structure, making it easy to connect to existing compressed air systems and plug and play, greatly improving the usability of the equipment.

Market prospects and development trends

According to market research reports, the 3D printing gas market is maintaining stable growth, with nitrogen being an important component.

Modularization, intelligence, and energy efficiency have become the main directions for the development of nitrogen generator technology. The latest generation of nitrogen generators is equipped with features such as purity monitoring, optional fail safe shutdown, and environmental protection mode, maximizing energy efficiency and reducing operating costs. With the penetration of 3D printing technology into more industries, the demand for efficient and economical gas solutions will continue to grow, and modular nitrogen generators are expected to become the standard configuration for more 3D printing enterprises.